OUR SERVICES

COMPRESSOR SERVICES

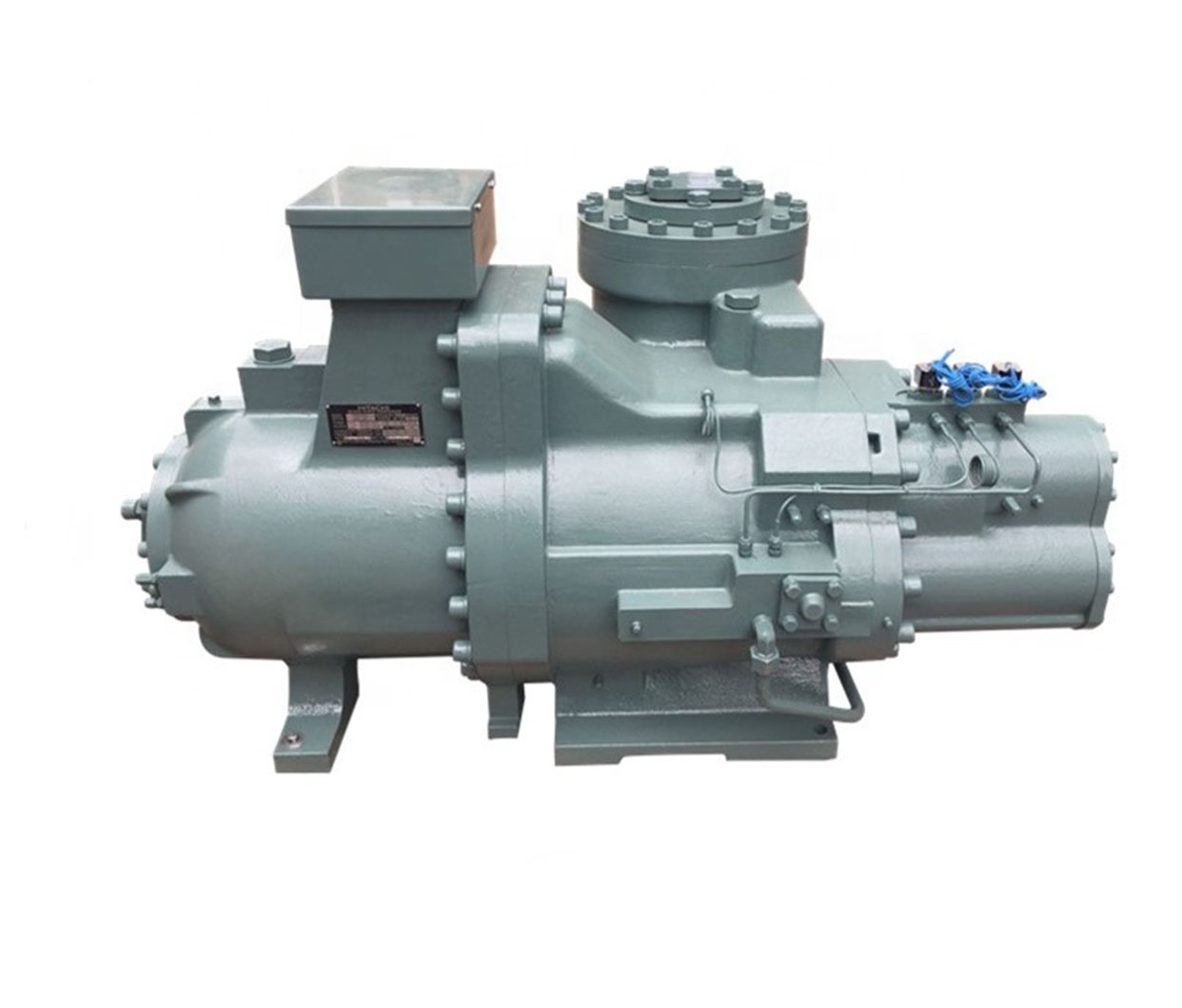

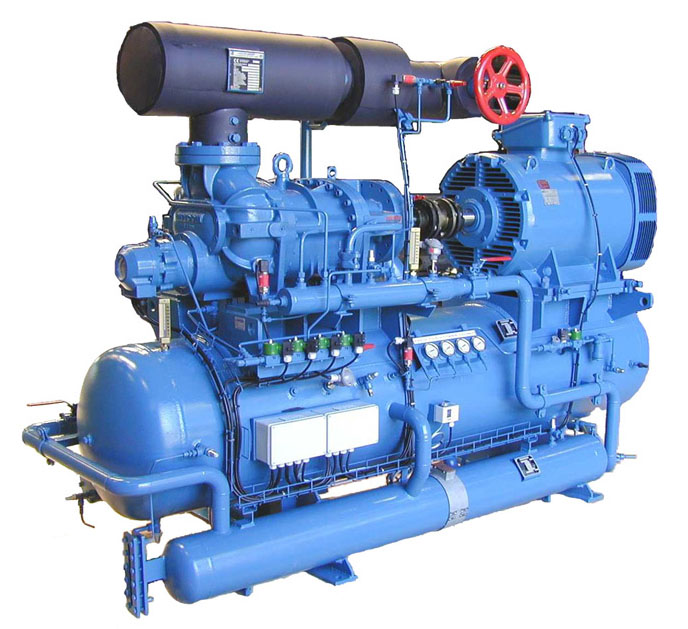

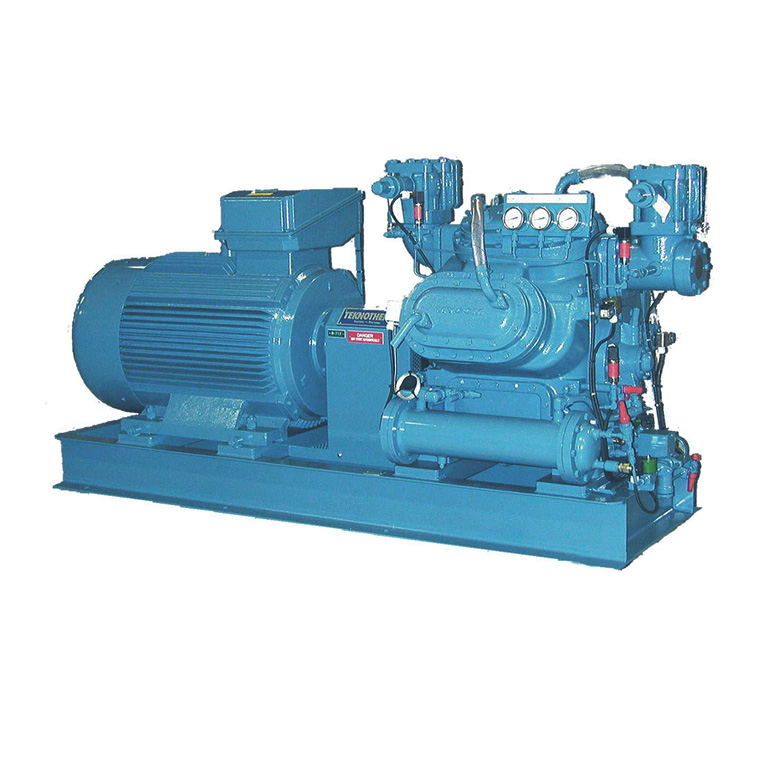

We offer Compressor overhauling includes a complete strip down and clean of the compressor all parts are checked for damage and all tolerances recorded and checked according to manufacturer’s recommendations. The compressor is then rebuild replacing any worn or faulty parts to the exact OEM recommended standard using OEM spare parts.

In cases where rotors or Crank shaft are found to be above manufacturer’s recommended wear limits these can be precision machined back to the original standard. From a motor rewind to a complete rebuild including a new crankshaft, there are few compressors beyond repair.

Even complex projects are managed and carried out efficiently. The company’s Service experts have mastery of all the necessary technologies used during repairs and overhauls. Professional project management guarantees on-time delivery and maximum quality.

OUR SERVICES

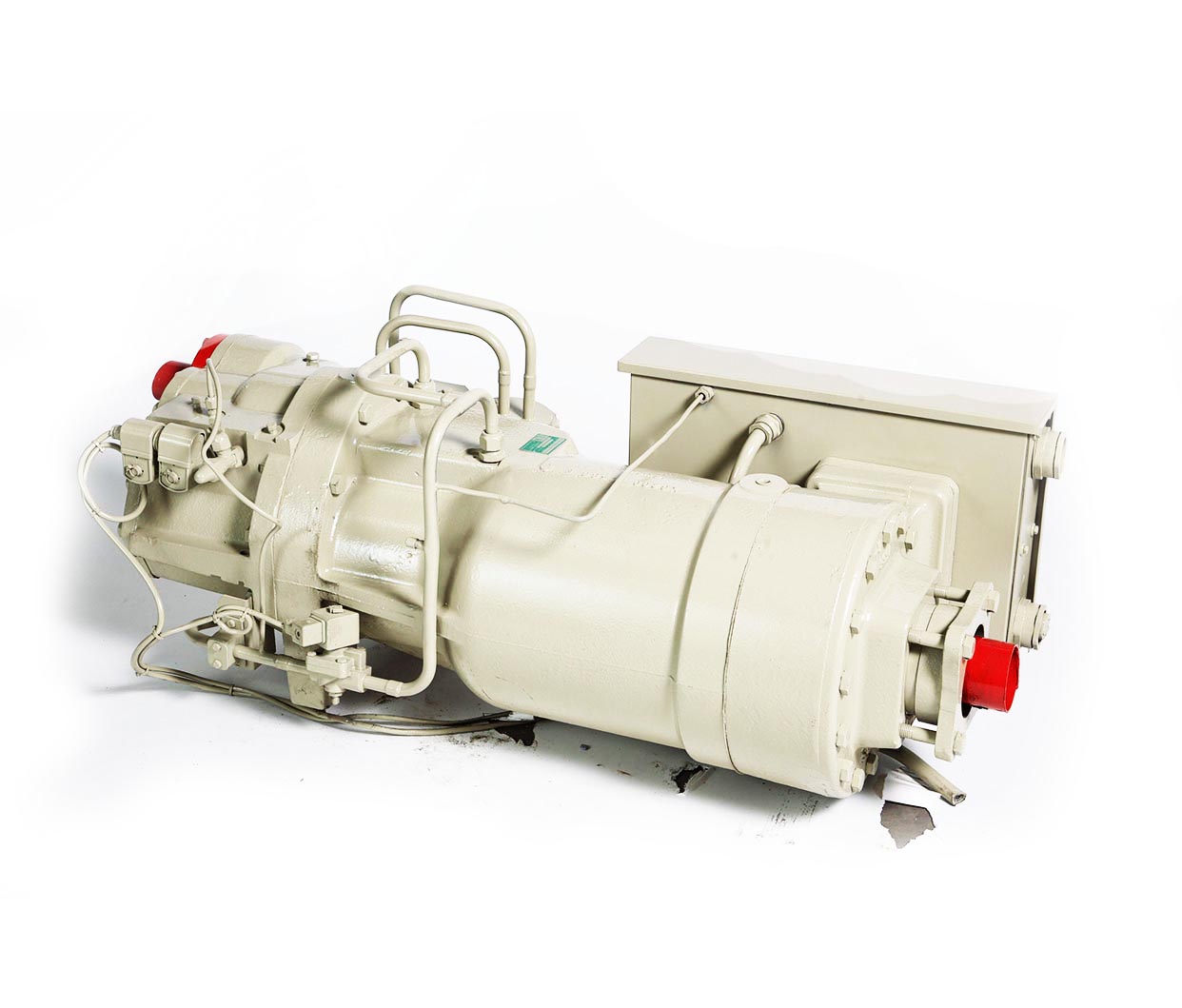

REMANUFACTURED COMPRESSORS

By monitoring trends and types arctic mount endeavour to hold comprehensive stocks of remanufactured refrigeration compressors ‘on the shelf’ ready for immediate despatch. Direct replacements ensure that downtime is kept to a minimum and the produce can be preserved.

If requested our experienced lift & shift teams can also remove the old and replace the newly remanufactured compressor, often within hours, with minimal disruption. This service is available nationwide.

OUR SERVICES

COMPRESSOR OVERHAULING &STATOR REWINDING

WE OFFER YOU

- Full inspection and overview of your compressor; with a technical report and quotation of the best and most economical solution.

- Compressor overhauling or reconditioning as required, testing, installation and start-up

- Compressor exchange

- Retrofitting of compressors on board

We have the capability to overhaul and recondition, in our own fully equipped workshop facility, open and semi-hermetic compressors of All Major Brands .

Articles

Stay up to date with

our fresh news

Environmental concern is a major factor for the need of an annual chiller maintenance. The responsible handling of all refrigerants…

The basic principles of refrigeration is happening in an HVAC chiller, Heating ventilation and air conditioning process is conducted to…

Without cold storage, most fruits and vegetables will not stay fresh for more than a few days. As soon as…

Maintaining Chiller throughout the year is crucial and we have to understand the common chiller problems which may affect normal…